International cooperation, the introduction of the patented technology of the Academician of the Institute of Heat and Mass Transfer of the National Academy of Sciences of Belarus.

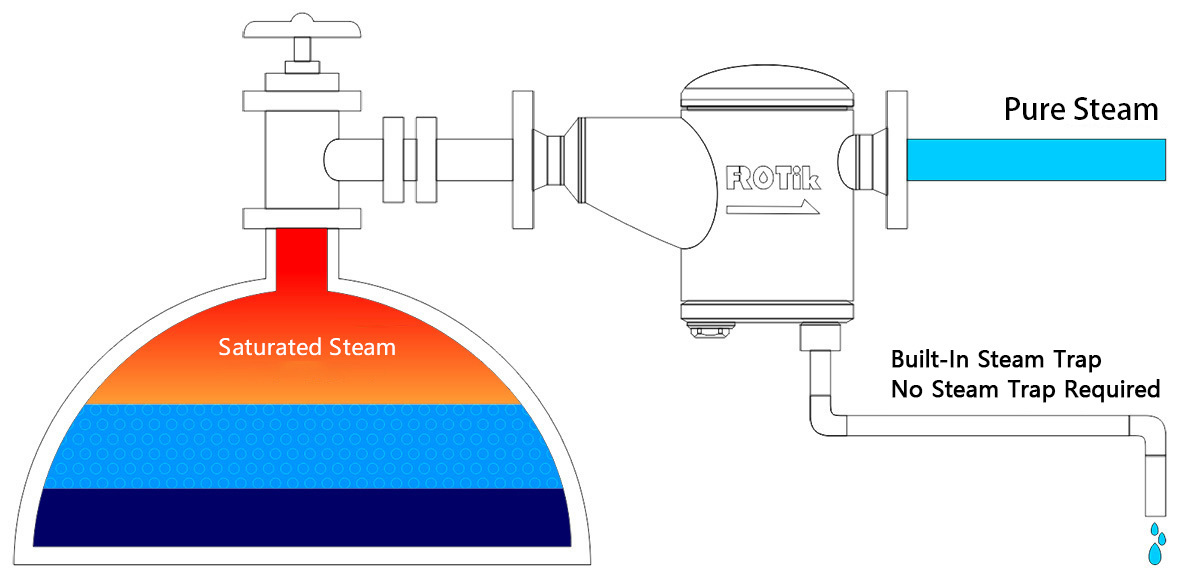

Unique turbine technology, using steam self-power to drive the turbine to reach centrifugal force, throwing out all the moisture in the steam, ensuring the steam dryness of more than 99%. Improve the heat exchange efficiency of steam.

Specification range: DN25-DN500(NPS1-NPS20)

Pressure class: PN10-PN160(CLASS150-CLASS 900)

Temperature range: -30℃-350℃

Connection type: Flange (RF RTJ) Weld end (BW)

Valve body material: WCB CF8 CF8M

Valve internals material: Town alloy turbine

Dry and wet separation: 99%

Steam quality optimization technology:It is to separate the small liquid droplets in the steam and gather at the bottom to be discharged by the discharge port, so that the dry gas is discharged by the outlet.

Through five stages of separation: deceleration, centrifugation, collision, direction change, condensation and other processes, remove the liquid medium in the medium, to achieve the role of purification.

Service Hotline

-

E-mail: frotik@frotik.com

-

Headquarters address : CNC9028C, 9F, Building C, Jiabo building, No. 189, Foshan Avenue, Foshan City

Factory Address: 2nd Floor, Room 102, Building 12, Liandong Yougu North Garden, No.1 East Second District, Jiansha Road, Danzao Town, Nanhai District, Foshan City

Steam Energy Saver - Saving energy for you

©2023 Rotik Engineering Co,.Ltd | SEO | Business License | Powered by: www.300.cn

©2023 Rotik Engineering Co,.Ltd | SEO | Business License

Powered by: www.300.cn