1. Whats Condensate Recycle Stytem?

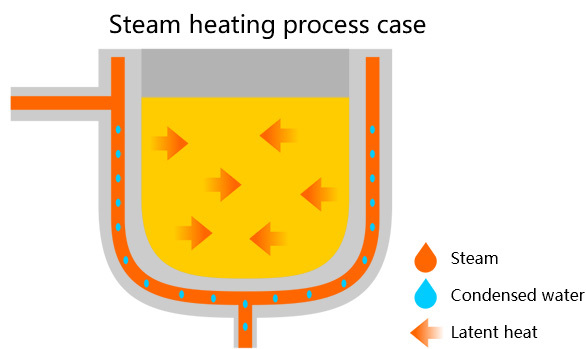

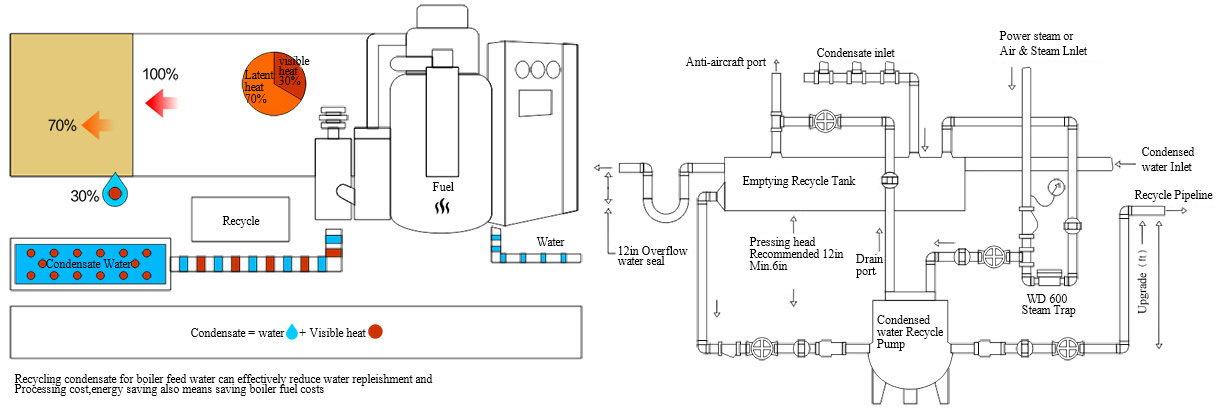

If a heating process requires 1th of steam, that means the equipment needs to discharge the corresponding mass (1t/h) of condensate. The recovery of water and sensible heat from the discharged condensate is called condensate recovery. Recycling condensate can significantly reduce energy consumption, water treatment andhydration costs.

2. Benefits of recycling condensate

Reusing high-temperature condensate will save investments in energy and water, while helping plants improve their working environment and reduce their carbon footprint

3. Reduce fuel costs

Condensate contains between 10 and 30 percent of the total heat of steam. Using higher temperature boiler feedwater maximizes boiler output because the boiler requires less heat to vaporize water into steam. Efficiency Recycle of heat energy can result in boiler fuel savings of about 10 to 20 percent.

4. Reduce the costs associated with water treatment

After removing the impurities trapped in the transmission, the condensate can be used for boiler feed water, reducing water costs and water treatment costs. In addition, in some areas there are requirements for the temperature of the condensate to be discharged, and recycling condensate can save the cost of replenishing cold water to neutralize the condensate temperature.

Pneumatic condensate recovery device condensate recovery diagram

Service Hotline

-

E-mail: frotik@frotik.com

-

Headquarters address : CNC9028C, 9F, Building C, Jiabo building, No. 189, Foshan Avenue, Foshan City

Factory Address: 2nd Floor, Room 102, Building 12, Liandong Yougu North Garden, No.1 East Second District, Jiansha Road, Danzao Town, Nanhai District, Foshan City

Steam Energy Saver - Saving energy for you

©2023 Rotik Engineering Co,.Ltd | SEO | Business License | Powered by: www.300.cn

©2023 Rotik Engineering Co,.Ltd | SEO | Business License

Powered by: www.300.cn